Huawei, Oppo, Apple, etc., are all manufacturers of mobile phone products that are inseparable from our daily lives. Smart phones involve a complex crossover of industries, one of high-tech industries such as high-tech information technology, electronic wafer technology, and digital signal communications. In addition, it is also an industry that requires a lot of labor and raw material consumption. In the assembly and inlay work of mobile phones, two methods are needed: metal fixing and adhesive fixing.

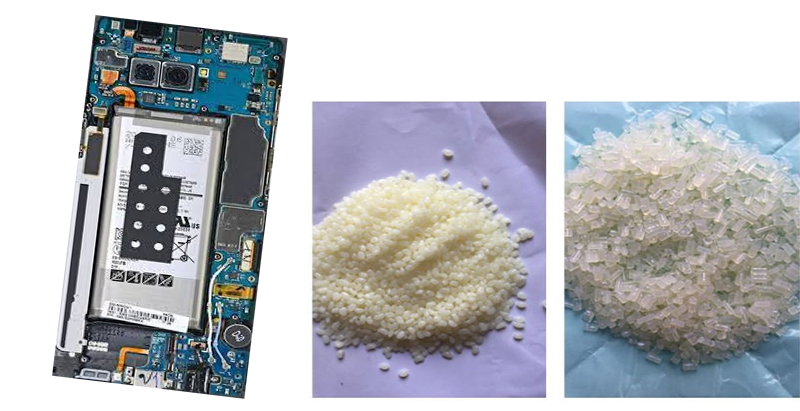

Adhesive fixation is to use hot melt adhesive pellets, etc., to finely process and bond some delicate parts, such as chips, touch screens and other parts. These parts cannot be forced to use metal to fix, otherwise it will easily cause damage to the panel and display. For other problems, it can be said vividly that no matter how professional or advanced the industry is, they also need small hot melt adhesive products to solve some problems for them.

For the hot-melt adhesive particles for bonding all parts of mobile phones, we usually use hot-melt adhesives such as EVA hot-melt adhesive and polyurethane hot-melt adhesive, because these hot-melt adhesives do not have high requirements for most of the bonding surfaces. The adhesion and holding power between metal, plastic and fiberboard are excellent, and the dispensing process of mobile phone parts under the hot melt of hot melt adhesive is simple, and the production can be completed by dispensing the parts and waiting for curing. Another advantage of products such as EVA hot melt adhesive and polyurethane hot melt adhesive is that their curing time is relatively short. After finishing the gluing of a mobile phone, basically the previous mobile phone has been cured, which is suitable for many mobile phone production. The assembly line production of manufacturers and agent processors enables them to quickly complete mobile phone production and enter the market.

Moreover, bonding the mobile phone with hot melt adhesive can also reduce the pressure on the machine itself, reduce the physical force of the body, and play a buffering role. We all know that when an all-metal solidified mobile phone is subjected to irregular external force, the external force will be amplified in the body, which will affect the fine electronic components of the board core over time. For all the metal inside the body, this situation will be further amplified. However, if hot melt adhesive is added for reinforcement, the hot melt adhesive can not only stabilize the adhesion inside the mobile phone, but also provide a buffer for external force absorption, reducing the repair rate and difficulty of the mobile phone, and extending consumers The service life of our mobile phones. Therefore, hot melt adhesive products are also a highly sought-after product in the mobile phone industry.

Pay attention to JORI, focus on hot melt glue machine gluing technology, and provide you with the most professional solutions and technical support!

Now It’s your turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.