Since the spread of COVID-19, the medical industry soon faced a serious shortage of personal protective equipment. Fortunately, JORI’s hot melt glue machine has already been used in protective clothing and other fields, and has begun to respond to challenges early to speed up the production of this key equipment, and has been deployed on one of the most important fronts in the fight against deadly diseases.

For many years, hot melt adhesive has been a key component in the production of various types of non-woven fabrics. The use of hot melt adhesive requires our glue machine. From the bonding of multilayer fabrics, hot melt adhesive is obtained during the entire assembly process. widely used. Even so, choosing the right hot melt glue machine for efficient production is essential for long-term reduction of production costs and maximizing your investment costs. Let us gradually understand the needs of protective clothing manufacturers when buying high-performance, large-capacity and high-speed hot melt adhesive machines.

Each stage of the production of protective clothing requires different hot melt spraying processes. According to your own work flow, you may need to use various applicators, as well as a large number of glue machine and hot melt hoses, at various positions of the production line. Your glue machine can also connect to the automatic and manual glue gun.

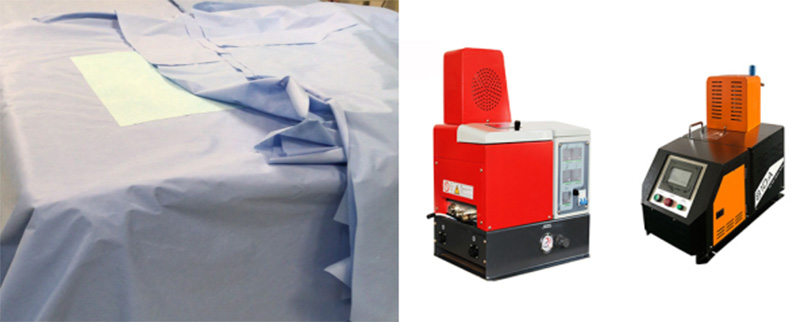

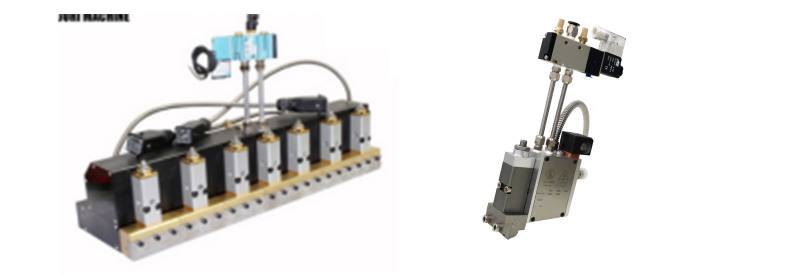

Automatic hot melt glue machine: The automatic glue machine with fiber gun is most suitable for large-scale fast and precise coating, also may require extrusion, spraying or precise slot die gun to ensure that the glue is applied in the correct amount in the correct position,but the medical protective clothing more common to use module gun with spray nozzle ,automatically set walking route map, or PLC import route map.Our customers used our glue machine to produce hundreds of thousands of medical protective products, including our protective clothing. On the first day, they produced 300 pieces. After the process was in place, they used automatic hot melt glue machine equipment. They quickly The output has been increased tenfold, and at least 3000 pieces are produced per day.

Manual hot melt glue machine: For smaller-scale applications of the medical protective clothing(for example, complicated manual design or on-site application of glue during the final inspection process), you may also need some handle gun, which are simpler and easier to operate.

Now It’s your turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.