The hot melt glue machine is very popular and has a wide range of applications. Let us introduce the glue main machine first below. Our hot melt glue mian machine have different glue tank capacity ,5L ,7L,10L(PLC new type and normal type) ,20L,30L,50L.you can according your need to choose. 5L glue machine structure: Firstly, this is the cap of hot melt glue tank. From here, you can add the hot melt glue block for melting, usually it is no more than 3/4 of the glue tank capacity. Also you can add the hot melt glue when you are using the machine. It needs 30-40 minutes for heating the glue, then the hot melt glue will be melting completely. Please be careful, don’t overflow when you are adding the glue. Secondly, you can see the Temperature controllers in the…

Continue ReadingBlog

How to use the dispenser glue machine in the mobile phone industry (circuit board)?

Huawei, Oppo, Apple, etc., are all manufacturers of mobile phone products that are inseparable from our daily lives. Smart phones involve a complex crossover of industries, one of high-tech industries such as high-tech information technology, electronic wafer technology, and digital signal communications. In addition, it is also an industry that requires a lot of labor and raw material consumption. In the assembly and inlay work of mobile phones, two methods are needed: metal fixing and adhesive fixing. Adhesive fixation is to use hot melt adhesive pellets, etc., to finely process and bond some delicate parts, such as chips, touch screens and other parts. These parts cannot be forced to use metal to fix, otherwise it will easily cause damage to the panel and display. For other problems, it can be said vividly that no matter how professional…

Continue ReadingHot melt glue machine safety manual

With the rapid development of various industries, flexible packaging has become the mainstream, making hot melt glue machines the “darling” of the packaging industry. In order to ensure the high-speed, high-efficiency, and high-quality operation of the packaging equipment, reduce the downtime caused by the hot melt glue machine, avoid safety hazards and increase the service life of the hot melt glue machine, the following discusses the use of the hot melt glue machine, Communicate with you about maintenance, cleaning and other related issues. Matters needing attention when using hot melt glue machine When operating the hot melt glue machine, do not place other sundries on the body or use it as a booster. When moving or lifting the hot melt glue machine, only its base is allowed to be used as a carrying point.…

Continue ReadingWhat are the common problems and solutions for hot melt adhesives?

In the process of using glue, due to the changes of various situations, various problems will be encountered. To solve these problems, it is necessary to have a comprehensive understanding and comprehensive analysis of various factors. To understand clearly: Temperature (substrate temperature, glue tank, glue roller temperature, ambient temperature), humidity (environment, sheet), thickness (edge banding, glue application), speed (opening, curing, feeding), surface degree (opening Accuracy, roughness), pressure (magnitude and direction), mechanical force (cutting force magnitude, direction), and then make specific analysis based on specific issues Common problems and solutions for hot melt adhesives: Serious discoloration of hot melt adhesive ➡Reason: ① The hot melt adhesive is contaminated, causing oxidation; ② The material deteriorates after being heated or high temperature; ③The fuser works for a long time without edge banding; ➡Solution: ① Clean the glue tank…

Continue ReadingCHOOSING THE RIGHT HOT MELT NOZZLE FOR YOUR NEEDS

In this post, we compiled an overview of hot melt nozzles to assist individuals with their research and make finding the right product a faster process. These accessories help control the volume, velocity, and direction of a hot melt adhesive being applied to a substrate. Nozzles come in three primary forms: bead, spray, and multi-line, which can be used for various manufacturing and assembly needs. Because of this fact, selecting the appropriate piece will help improve users’ product output, and quality and help cut down on waste. Below we outline the steps you can take to ensure you identify the correct hot melt nozzle. We also discuss different models carried by Glue Machinery Corporation. Lastly, we provide some basic maintenance tips to help you get the most out of your purchase. HOW TO FIND THE…

Continue ReadingPOLYURETHANE HOT MELT ADHESIVES WHAT YOU NEED TO KNOW

When deciding what kind of adhesive to use for your manufacturing, packaging and labeling needs, you may consider a moisture-curing polyurethane hot melt adhesive (PUR). With their high bond strength, polyurethane hot melts can be an attractive option for many different kinds of adhesive applications. However, polyurethane hot melts are not without their disadvantages as well. Let’s take a closer look at the pros and cons of using polyurethane hot melts for your particular adhesive needs. ADVANTAGES OF POLYURETHANE HOT MELT ADHESIVES STRONGER THAN WATER-BASED & OTHER HOT-MELTS ADHESIVES: PUR hot melt draws moisture from the substrates and the atmosphere and cures to form a bond that is stronger than most other adhesives, including water-based adhesives as well as other hot melt adhesive formulations. SHORT LEARNING CURVE: Because polyurethane hot melt adhesives are applied like other…

Continue ReadingHow to solve the problem of hot melt adhesive drawing?

Hot melt adhesive is a kind of plasticity EVA,APO ,Resin..etc adhesive, and its physical properties will change with temperature within a certain temperature range. In the process of using hot-melt adhesive, some customers will find that hot-melt adhesive will have wire drawing. Hot-melt adhesive wire drawing will not only affect the construction efficiency, but also affect the appearance of the product, and more likely affect the bonding effect. So how to solve the problem of hot melt adhesive wire drawing? First of all, we need to understand the reasons why hot melt adhesive produces wire drawing, and solve the problem according to different reasons. 1.The temperature of the hot melt glue machine is low The low temperature of the hot melt glue machine will increase the thinness of the glue and cause wire drawing. Therefore,…

Continue ReadingAutomatic glue system instead of manual gluing

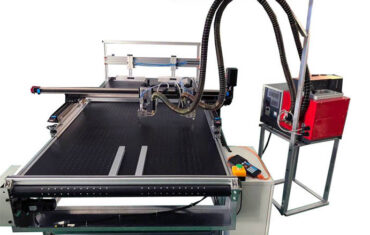

Automatic hot glue machine are a common piece of hot melt dispensing equipment used in a variety of industries, such as packaging and construction. Finding the right fit, however, for your application can be a challenge. With that in mind, we have compiled instruction about automatic hot melt glue machine. Part 1: Structure of automatic glue machine The machine is mainly consisted of 6 parts – Glue Hose, Glue Table, Glue Gun, Glue Tank, Remote Control and Dispensing Glue System. Part 2: Gun type of automatic glue machine Automatic glue machine can use different type glue gun. One is dot&line type gun. This gun suitable for box packing, carton box and book cover One is glue fiber gun, this is spray type gun, usually suitable for protective suit, Sanitary napkins and diapers. One is slot die glue gun.…

Continue ReadingJORI MACHINERY SOLUTION FOR BOOKBONDING

What is the glue bonding: Glue bonding is the process of connecting individual pages into a whole volume. The history of book bonding using hot glue: The monks copied the libtaried before inventing the Bookpress,in the 1447 the Gutenberg’s invention wad brought to the street,but people still bonded thee book by their hand.Early the twentith Centry the invention of Sewing Machine emerged and the Bookk bonding using glue had been invented after that.In 1868, David Smyth developed the gluing book methods and most of his method are still in use today.In 1940s thee Dupont developed the hot melt adhesive for glue bonding, which has a strong elasticity for bonding book. Which kind of Glue Machines can be used in the process of glue bonding. Blue Small Glue Machine: Easy moved, They don’t take up…

Continue ReadingApplication Hot melt glue machine in Packaging Box,Gift Box

Hot melt glue machine is a common production and packaging machinery, it is widely used in different industries,80% of hot melt glue machines are used in the carton industry.So what is its specific application in the packaging box products industry? Packaging box products industry: As shown in the picture,this is cake packaging box,it is firmly,and the glue is very even no leak.It only needs to stick the plastic film inside the box. The gift packaging box,it can be glued firmly on both sides of the box through a hot melt glue coating machine. Hot melt glue machine advantages: Fast!The whole gluing process only takes 1-3 seconds to complete(even faster). Occupy less space, hot melt glue machine shape is small, only need a small space. Lowest production cost per unit product. Good gluing effect and high gluing strength. No waste…

Continue Reading