Traditional hot melt adhesives (also known as thermoplastic adhesives) are one hundred percent solid, except when heated above a temperature of between 160°C and 180°C. The substance rapidly cools and sets, creating a quick and strong bond. The adhesives can be either very rigid or soft and pliable, depending on what the material is composed of. Hot melt adhesives are compounded from thermoplastic polymers and plastics. They are not affected by moisture, water, or humidity, unlike many other bonding agents. Hot melts are prominently used in the markets of automated manufacturing lines, packaging, converting, footwear, product assembly, bookbinding, and many more. The materials used to make up the hot melt adhesive usually depend on what purpose it will serve. Unlike solvent and water-based adhesives, there is no drying time with hot melt, so its uses are expanding…

Continue ReadingBlog

Are Disinfectant Wipes Out of Stock? The Glue Coating Machine is Here!

Excessive demand and insufficient output Benno Dorer, chairman and chief executive officer of Clorox, the world ’s leading disinfectant wipes, introduced that consumer demand brought by the new corona virus surged by 500%,although the current output has increased by 40%, the disinfectant wipes they produce are still insufficient In the current demand;same in an interview with Yahoo Finance, he also explained that the company made adjustments and found a new way of “accelerating the production line” to try to fill the shelves”,we are activating suppliers that help us. We are investing to increase capacity”. Yes, as Benno Dorer said, we need to cooperate with suppliers. The production of disinfectant wipes is an industrial chain that requires two basic elements: labor and raw materials; The new coronavirus is a global outbreak. In order to reduce the spread,…

Continue ReadingHow to Choose The Hot Melt Adhesives for Filter Assembly and Manufacturing

Effective filtration is becoming increasingly important in today’s world. Whether it’s the air inside your house, the drinking water in an urban metropolis or the fuel in a heavy-duty vehicle – filters are being asked to do more. In turn, filter manufacturers turn to us when they need to accomplish more with their filter adhesives. Air filters in vehicles and buildings are high-performance products. They ensure a constant supply of fresh and clean air. Filters are very diverse and are frequently composed of different materials. Powerful hot melt adhesives for the manufacture of filters are not only characterized by a broad range of adhesion to the different materials but also facilitate superior products and efficient manufacturing processes. How are hot melt adhesives used in filter assembly? Hot melt or water-based adhesives are used in the final stages of…

Continue ReadingDaily inspection items of melter

(Part One) During the use of the melter, daily maintenance and inspection can not only eliminate and find faults, but also better maintain the equipment and extend the service life of the machine. DAILY CHECK LIST Heating Confirm that the device is turned on and heated. There are three ways to start heating: (1) Timer (2) Remote host control (3) Manual switch Heating may take about 40 to 60 minutes Initial inspection as required Necessary conditions: wear safety protective equipment Once the problem is found: → Report to supervisor or maintenance personnel Compressed air Check air supply Leak Check the diverter valve for leaks: → Check for new hot leak adhesive Check if the screw connection is tight Check if the filter screws are tight Check whether the pressure relief valve is…

Continue ReadingApplication of Hot Melt Glue Machine in Face Mask.

2L Hot Melt Glue Machine for the Disposable Face Mask Face Masks have the role of isolation and protection, such as viruses in the blood, respiratory droplets, and contamination of body fluids…etc For ear loop of disposable face masks, we can use our common 2L hot melt glue machine with dot nozzle . Hot Melt Glue Coating Machine For the N95 Mask. Do you know the aluminum strip on the nose bridge of the N95 mask? Which is use our hot melt glue coating machine.The whole aluminum plate is glued and then cut into small strip pieces. Features of the gluing machine Simple operation Manual control Convenient and fast The best choice for economical,can be mass-produced by workers. 2L Pedal Type Glue Dispensing Machine https://www.jorimachinery.com/2l-pedal-type-glue-dispensing-machine/ A Helpful Tool for industrial production-Roller Glue Machine https://www.jorimachinery.com/a-helpful-tool-for-industrial-production-roller-glue-machine/

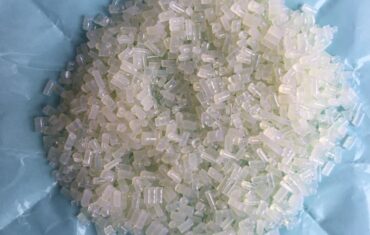

Continue ReadingHot Melt Adhesive For Hot Melt Glue Machines

Hot Melt Adhesive For Hot Melt Glue Machines Hot melt adhesive Hot melt adhesives are thermoplastic materials composed of stabilizers, additives, pigments and polymers. They are usually produced by hot melt glue machines and sold as solid, cylindrical rods or pellets. Sticks are melted and applied using a hot melt spray gun or sprayer. Hot-melt adhesive components Hot melts adhesive consists of three main components: high molecular weight polymers, adhesives and plasticizers. Polymer as the main adhesive. Tackifier or resin provides more adhesion and wetting properties. The ability of plasticizers (wax or petroleum) to control viscosity and small machinery is easy to dispense. Advantages of hot melt adhesive The excellent combination of hot-melt adhesives and the application of fast adhesion make hot-melt adhesives particularly suitable for multi-functional packaging applications. Hot melts have a much longer shelf life than solvent adhesives. The…

Continue ReadingHow To Maintain Hot Melt Glue Box Sealing Machine?

Maintenance of the hot melt glue box sealing machine not only aimed at ensure that the machine is kept safe and in standard working condition, It is also an important factor in maintaining the stability of the packaging machines and the efficiency of the production lines. The hot melt glue box sealing machine must be handled and maintained by highly trained personnel to avoid damage to the equipment, burn injuries, and fires hazards. In this post, we will focus on the various applications of the hot melt glue box sealing machine such as wrapping, sealing and more. However, parameters such as temperature and other maintenance requirements of the hot melt glue box sealing machine is subject to the manufacturer’s standard and instructions, all of which are available in the user manual. Maintenance of the hot melt glue…

Continue ReadingHOW ADHESIVE MACHINERY IS USED IN FURNITURE MANUFACTURING

Features: Furniture manufacturers rely on hot melt equipment and other industrial adhesive machinery for a range of critical applications. From ensuring drawers are properly bonded to creating beautiful trim on all sorts of wooden furniture, adhesives are used for many different important purposes. The right adhesive machinery can help furniture manufacturers produce higher quality products in a more efficient manner, helping drive customer loyalty and boosting the bottom line. Some of the technical processes in furniture manufacturing that rely on adhesives and adhesive machinery include: Edge banding: Edge banding is a process used to place a narrow strip of trim around the edges of a piece of furniture to create a smooth, beautiful and durable finish. This process is used a lot on furniture built with plywood or particle board as it gives it a more attractive…

Continue Reading