Hot melt glue box sealing machine is a hot-selling box sealing machine in recent years. It is widely used in various industries with its characteristics of non-toxic, odorless, economical, environmental protection, and food grade,especially for the food and pharmaceutical industries, it requires more high, the box sealing machine just meets the application market of small box. The machine has a compact structure and a small footprint (some customers use it directly in the garage or at home). The key is the use of large-area stainless steel plates, and the food grade characteristics of hot melt glue,such as biscuits, coffee, snacks, and hygiene products, make it the best choice for small box applications. It is also particularly cheap. The investment cost is very low, which increases production efficiency and reduces production costs.

Hot melt box sealing machine refers to semi-automatic manual box feeding,which function is to push the box manually and apply glue automatically.

Instructions for Hot Melt Box Sealing Machine:

1: When the device is used for the first time, please connect the load capacity should be greater than 15A

2: Equipped with air supply source to ensure pressure from 0.8MPA to 0.5MPA

3: Turn on the heating switch and heat the left and right glue tanks. For box-type hot melt glue, the temperature setting is 160℃ ~ 180℃ is suitable . In actual use, the temperature can be adjusted.

The temperature setting principle is based on the fact that the dispensing claw is raised to the box and returned without drawing;

If the temperature is too high, the hot melt glue will be carbonized, the teflon coating of the glue cylinder will fall off, the hot melt glue will turn yellow, and the viscosity will decrease.

Too low temperature will cause difficulty in lifting, cause large amount of glue and drawing

In short, the temperature setting is a non-negligible part of sealing the box. Please refer to the instructions for the use of the thermostat. It is advisable to adapt the sealing to the lowest possible temperature.

4: Adjust the specifications suitable for the folding of the box. The adjustment of the mechanical part is the key to the effectiveness of the machine. The adjuster must constantly explore. Generally speaking, the manufacturer will arrange the debugger or adjust it directly. (JORI hot melt glue box sealing machine has been adjusted according to customer needs before delivery, and the adjustment baffle configured as required is very easy to adjust. It can be changed in a few minutes. Please contact us at any time if necessary!)

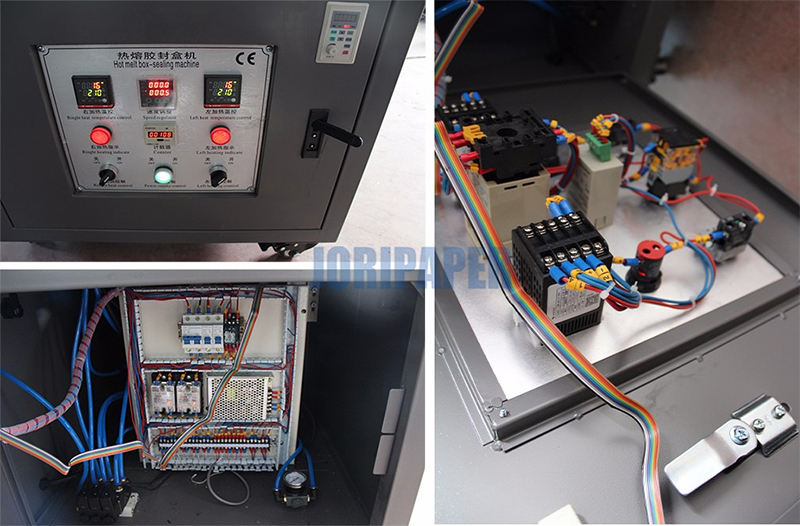

Details of JORI Hot Melt Glue Box Sealing Machine