In the process of using glue, due to the changes of various situations, various problems will be encountered. To solve these problems, it is necessary to have a comprehensive understanding and comprehensive analysis of various factors. To understand clearly:

Temperature (substrate temperature, glue tank, glue roller temperature, ambient temperature), humidity (environment, sheet), thickness (edge banding, glue application), speed (opening, curing, feeding), surface degree (opening Accuracy, roughness), pressure (magnitude and direction), mechanical force (cutting force magnitude, direction), and then make specific analysis based on specific issues

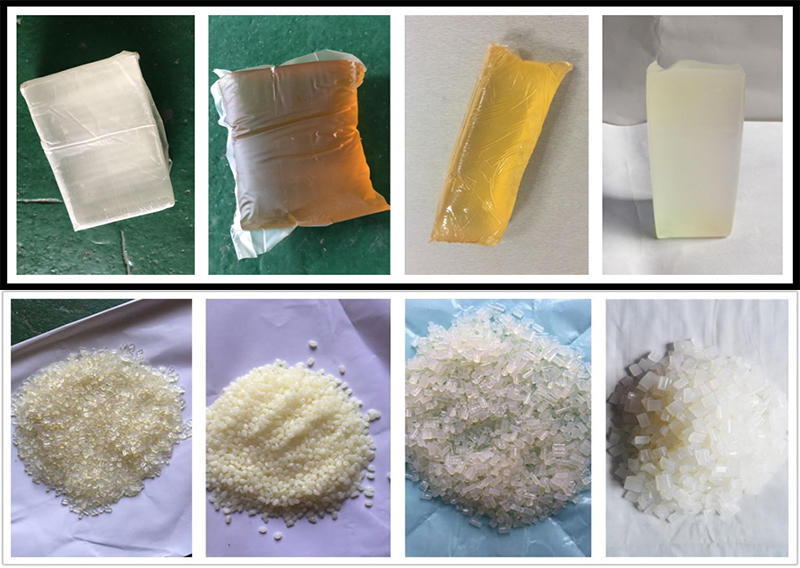

Common problems and solutions for hot melt adhesives:

Serious discoloration of hot melt adhesive

➡Reason:

① The hot melt adhesive is contaminated, causing oxidation;

② The material deteriorates after being heated or high temperature;

③The fuser works for a long time without edge banding;

➡Solution:

① Clean the glue tank regularly, and protect the glue tank at ordinary times;

②Regularly use a temperature measuring gun to check whether the glue usage temperature is consistent with the displayed temperature;

③ When the melter is suspended for more than 1 hour, the equipment temperature drops to 100-120℃;

The nozzle or hose is blocked

➡Reason: the hot melt glue is too sticky; carbide or gel is produced; there are foreign bodies in the glue bucket, etc.

➡Solution:

①Increase the temperature or use low-viscosity hot melt adhesive

②Clean the glue system or lower the temperature, change the glue

③Clean the glue tank and standardize glue adding

Dripping, running glue

➡Cause: The nozzle is dirty and damaged; there are foreign objects and wear in the nozzle valve; the solenoid valve is loosely installed and leaks; the air pressure is unstable and underpressure

➡Solution:

①Clean the nozzle,

② Overhaul or replacement

③ Reinstallation confirmation

④ Reset and check to meet the requirements

Hot melt glue splash

➡Reason: The glue pressure is too high; the temperature is too high; the viscosity is too low; the nozzle position is incorrect

➡Solution:

①Adjust the air pressure of the glue pump of the glue machine to reduce the pressure;

②Reduce the temperature;

③Reduce the temperature and reduce the distance between the spray gun and the object;

④Change the nozzle position

Hot melt adhesive solidification

➡Cause: Two kinds of immiscible glues are mixed; overheating; hot melt glue is unstable

➡Solution:

①Clean the glue tank, standardize the glue change, and find suppliers;

②Reduce the temperature, clean the plastic tank, and find a supplier;

③Clean the plastic tank and find a supplier

Hot melt glue drawing

➡Reason: The operating temperature is too low; the temperature of the glue in the tank is too low; the spraying time does not match the speed of the carton; the nozzle switch is worn; the old glue exceeds the service life in the glue tank

➡Solution:

① Increase the temperature (note: too high a temperature will affect the thermal stability of the glue);

②Pre-heating;

③Adjust the machine;

④ Clean and repair the nozzle;

⑤Clean the system and add new hot melt adhesive

Hot melt glue cannot flow evenly from the nozzle (gluing)

➡Reason: the nozzle is blocked; the air pressure is not enough in multiple groups of nozzles; the operating temperature is too low

➡Solution:

①Clean, overhaul, and replace;

②Check the quality of hot melt adhesive, carbonization, impurities, and glue change;

③Check the air pressure stability of the spray gun, check the nozzle and nozzle;

④ Increase the temperature, contact the supplier to increase the temperature

Hot melt glue smoking

➡Reason: The operating temperature is too high; the temperature control is out of control; the thermal stability of the hot melt adhesive is too poor

➡Solution:

①Reduce the temperature and find a supplier;

②Replace out-of-control components and find equipment vendors;

③Standardized change of glue, looking for suppliers

Bad bonding

➡Reason:

①The hot melt adhesive is mainly on the side of the substrate due to insufficient amount of glue or low operating temperature;

②Because the hot melt adhesive is subsequently affected when it is in a semi-molten state, there are glue on both sides of the substrate, but there are many solidified thin “feet”;

③The surface to be bonded is not in contact or in poor contact, and the surface of the hot melt adhesive is smooth;

④The bonding is easy to be separated. It is usually due to improper selection of the adhesive.

➡Solution:

①Increase the coating thickness or increase the temperature;

②Check whether the pressing is good, lower the operating temperature, or use a fast curing adhesive;

③Adjust the pressure to ensure good contact with the substrate during the cooling process of the hot melt adhesive;

Poor penetration of hot melt adhesive

➡Reason: the temperature is too low; the glue layer is too thin; there is a coating on the surface of the cardboard (such as wax or oil)

➡Solution:

① Increase the temperature;

② Increase the temperature and pipeline pressure, increase the amount of glue;

③You can try hot melt adhesives with different properties, or treat the surface of the cardboard;

Now It’s your turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.