Hot melt adhesive is a plastic adhesive. Its physical state changes with temperature in a certain temperature range, and its chemical properties remain unchanged. It is non-toxic and tasteless and is an environmentally friendly chemical product. Because the product itself is solid, it is convenient for packaging, transportation, storage, solvent-free, non-polluting and non-toxic; and has the advantages of simple production process, high added value, large bonding strength and high speed.

Today,we will introduce four main kinds of hot melt adhesive as following:

First, hot melt pressure sensitive adhesive

Mainly used for women’s sanitary napkins, children’s diapers, sick mattresses, old age incontinence products.

The technical indicators for this use of hot melt are as follows:

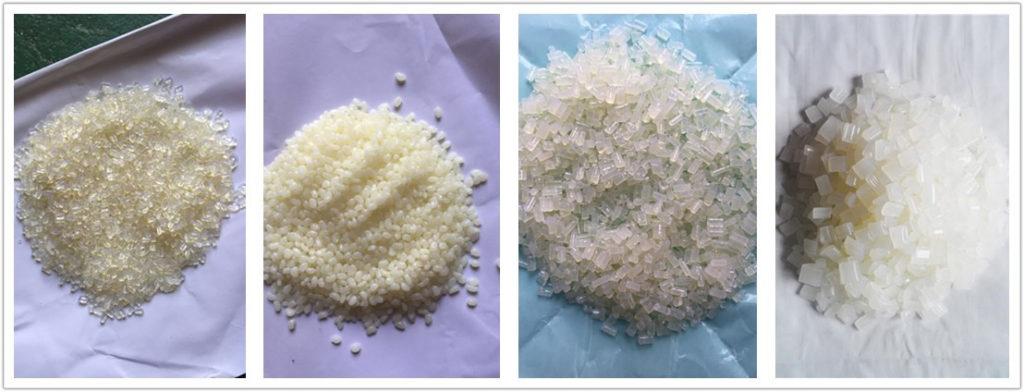

Appearance: white or yellowish block viscoelastic, solid;

Melting point: 80-90 °C;

Bonding strength: 2.0-2.51g/25mm;

Hygienic requirements: odorless, non-toxic, non-irritating to the skin.

Second, multi-purpose solvent type hot melt adhesive

In the production of many products, such as: hot melt transfer, liquid crystal material sealing, wallpaper security, painting and calligraphy, computer printing, food production date typing, wire and cable agent coding, etc. are all applications of hot melt, but can not be used Some granular or powdery dosage forms can be used in the production of subsequent processes without being formed into a liquid form in the presence of a suitable solvent and applied to a substrate to obtain a thin and uniform film.

Due to the different types of solute (hot sol), solvent-based hot sols can be produced for a variety of uses.

Third, the furniture edge sealing with hot melt

In addition to the use of solid wood in a small number of high-end furniture, furniture is usually made of fiberboard, shavings or sawdust, and the edge of the furniture sheet must be bonded with a hot melt to add edge to the material, adding beauty and resembling solid wood furniture.

The technical indicators for this use of hot melt are as follows:

Appearance: white is yellowish granular or rod-shaped.

Melting point: 70-84 °C;

Viscosity: 45000-75000 (180 °C).

Relative hardness: 70-80%;

Curing speed: 8-12 seconds.

Fourth, thermoplastic powder coating

There are two main categories of polyethylene (CDPE) and polyvinyl chloride (PVC) powder coatings.

It is used for cage fish farming, road guardrails, bicycle baskets, racks, refrigerator partitions, electric fan covers, etc. It is made into various colors according to needs, and it is applied to the surface of metal products to protect and decorate.

Performance: LOPE coating PVC coating;

Color: Selected according to usage;

Particle size: 80-120;

Metal adhesion: good.

The above is the scope of the hot melt adhesive, hope it to be helpful to everyone.

Now It’s Your Turn

I hoped you enjoyed my detailed information for starting a hot melt glue business .

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.